To prevent typical scaffolding mistakes, adhere to finest techniques: plan carefully for safety and effectiveness, select top notch materials like steel or light weight aluminum, warranty safe setting up making use of proper attachment methods, provide thorough employee training on secure methods, apply autumn prevention measures like guardrails, and observe regulations via routine inspections and paperwork. Proper planning, product choice, setting up, worker training, safety measures, and compliance with policies are vital. This concise guide highlights important steps in scaffold safety.

Reliable scaffolding preparation is important for making certain the safety and performance of construction tasks. Proper layout and reliable use of scaffolding are critical aspects that must be considered during the planning phase. Proper style includes creating a comprehensive format that takes into consideration the specific needs of the project, including the elevation, weight capability, and load-bearing capabilities needed. By making certain the scaffolding is made appropriately from the beginning, potential hazards and security dangers can be reduced.

Reliable use of scaffolding entails using the framework in a manner that makes the most of productivity while preserving security criteria. This includes guaranteeing that the scaffolding is put up according to the manufacturer's guidelines and sector guidelines. Appropriate training of employees on exactly how to make use of the scaffolding correctly is additionally necessary to stop mishaps and injuries on the construction website. Furthermore, regular assessments and maintenance of the scaffolding are critical to recognize any kind of problems beforehand and resolve them promptly.

Selecting the appropriate scaffolding materials is a crucial choice that substantially influences the security and efficiency of building and construction jobs. Proper maintenance and material choice are crucial aspects to contemplate when picking the best scaffolding materials.

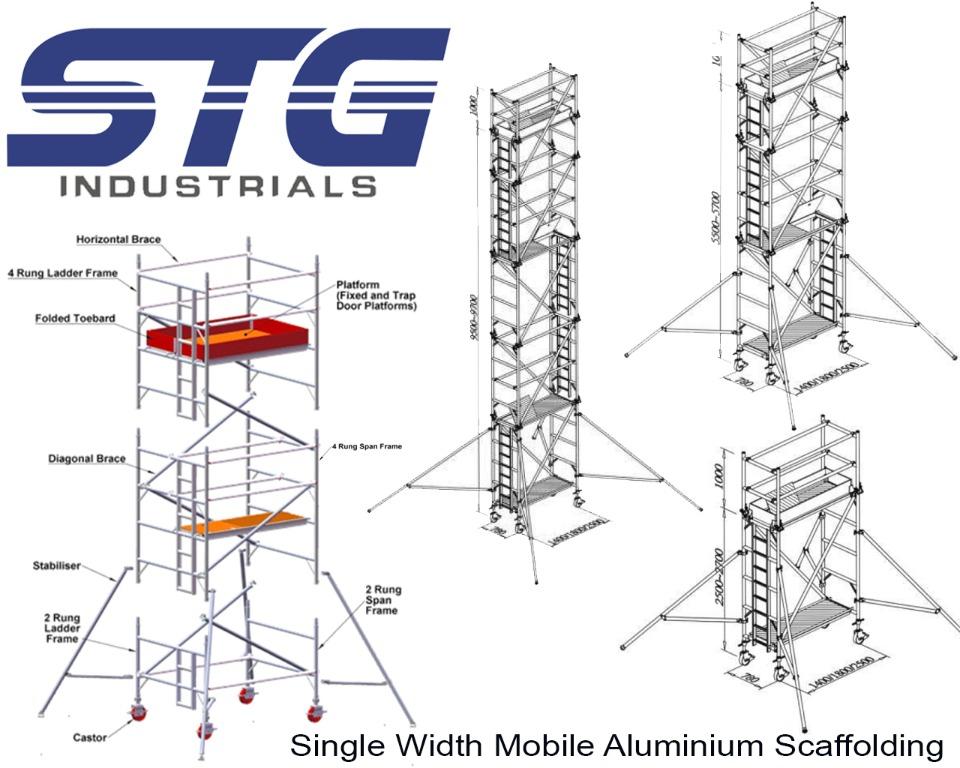

When it involves material option, it is important to choose premium products that meet security standards. Steel and aluminum are common selections due to their toughness and stamina. Steel scaffolding is robust and suitable for sturdy tasks, while aluminum scaffolding is lightweight and corrosion-resistant, excellent for tasks calling for regular setting up and disassembly.

Proper upkeep of scaffolding products is important to guarantee their durability and security. Regular examinations need to be performed to identify any indications of wear and tear, corrosion, or damages. Any kind of harmed parts need to be repaired or replaced promptly to prevent mishaps on the building and construction website.

To assure safe and secure scaffold setting up, it is essential to adhere to a precaution list, conduct proper equipment assessments, and employ protected attaching methods.

These methods are vital in preserving a risk-free work environment and preventing mishaps or injuries on construction sites.

Guaranteeing a safe scaffold setting up demands precise focus to safety measures throughout each step of the building procedure. Security training plays a vital duty in furnishing employees with the knowledge to identify possible risks and execute correct safety protocols.

Before beginning job, guaranteeing that all personnel involved have undergone detailed safety training is essential to stop crashes and injuries. Furthermore, thorough devices examination prior to scaffold assembly is vital to confirm that all parts remain in excellent condition and meet security criteria.

Routinely checking tools, materials, and the scaffold framework itself can assist determine any possible risks and ensure a safe workplace for all employees involved in the setting up process.

Evaluating the tools thoroughly prior to scaffold assembly is a vital action in making sure a safe and secure workplace for all personnel involved. To ensure tools security and correct capability, follow these evaluation treatments:

Aesthetic Examination: Check for any visible damages, corrosion, or missing parts on all parts.

Useful Examining: Make certain that systems such as locking pins and adjustable components are working properly.

Lots Capability Confirmation: Confirm that the scaffold can securely support the desired weight by assessing maker specifications and capacity tags.

Sticking to these assessment treatments is necessary in preserving a risk-free scaffolding setup. By prioritizing equipment safety with detailed examinations, the risk of accidents and injuries can be dramatically decreased.

Maintaining a safe and secure scaffold assembly depends greatly on implementing precise and trusted fastening methods. Fastening security is extremely important to ensure the security and stability of the scaffold framework. https://edgwarescaffolding.co.uk

Protected connections in between various scaffold elements, such as structures, braces, and systems, are important to prevent crashes and structural failures. Making use of suitable bolts and following manufacturer guidelines for tightening torque specs are important action in achieving a durable scaffold assembly.

Inspecting fastenings on a regular basis for indications of wear, rust, or loosening is likewise vital to maintain the stability of the scaffold. By focusing on attaching security and making certain secure links throughout the scaffold, building and construction teams can substantially reduce the threats related to scaffold assembly and usage.

Normal examination and upkeep procedures are important aspects of making certain scaffold safety. Scheduled evaluations assist recognize prospective concerns prior to they escalate, while punctual repair work address any kind of concerns immediately.

Paperwork of these procedures is crucial for governing compliance and preserving a risk-free working environment.

To assure the safety and security and longevity of scaffolding structures, essential checks and prompt maintenance are essential methods. Implementing a detailed safety audit and adhering to a stringent evaluation schedule are important elements in making sure the architectural honesty of scaffolding.

Right here are three important steps to ponder:

Examining scaffolding on a regular basis for security is critical to immediately attend to any type of fixings needed to preserve architectural stability. Prompt repairs are required to ensure the security of employees and the stability of the structure. Establishing regular upkeep schedules can aid in identifying possible concerns early on.

Routine examinations should consist of looking for loosened screws, harmed elements, or any kind of indications of wear and tear. Any type of identified issues ought to be dealt with quickly by certified employees to stop crashes or architectural failings. Maintaining comprehensive documents of maintenances can aid in tracking the scaffolding's problem with time.

Implementing an extensive documentation system for compliance with regular assessment and maintenance treatments is vital for ensuring the safety and security and structural integrity of scaffolding. To achieve this, take into consideration the following:

Normal Evaluations: Conduct arranged inspections to recognize any issues immediately.

Upkeep Records: Keep thorough records of upkeep tasks and fixings.

Security Training Paperwork: Guarantee all workers involved in scaffolding work have actually obtained proper safety and security training and maintain records to show conformity.

Appropriate training of employees on risk-free scaffolding methods is necessary to assure a safe and secure workplace on construction websites. Worker guidance plays a crucial duty in seeing to it that workers adhere to security procedures when servicing scaffolding. Security training should cover proper setting up and disassembly of scaffolding, right installation of guardrails and toe boards, risk-free handling of materials on raised systems, and treatments to prevent drops. It is vital that employees are skilled in recognizing prospective dangers, such as unstable ground problems, above high-voltage line, or stormy climate, and recognize just how to alleviate these dangers successfully.

Normal safety conferences and correspondence course can help strengthen the relevance of risk-free scaffolding techniques and maintain workers educated about any updates in security guidelines. Companies ought to also offer access to personal safety equipment (PPE) and make sure that employees are learnt its correct use. By prioritizing extensive security training and constant worker guidance, construction firms can lower the probability of scaffolding crashes and develop a safer work environment for all workers included.

To assure a safe and secure working environment on building and construction sites, stringent adherence to scaffolding guidelines is imperative. Regulatory compliance and safety and security criteria must go to the forefront of every building project to minimize threats and make certain the health of workers.

Here are three bottom lines to consider pertaining to compliance with scaffolding regulations:

Regular Evaluations: Conduct regular examinations of the scaffolding framework to recognize any potential dangers or issues that can endanger its honesty. Examinations should be performed by qualified professionals and documented as necessary.

Training and Certification: Make sure that all workers working on or around scaffolding are properly educated and certified to do so. This includes understanding safety and security protocols, correct assembly, and dismantling treatments, as well as emergency situation reaction actions.

Documentation and Record-Keeping: Keep detailed documents of evaluations, training qualifications, and any modifications made to the scaffolding. Paperwork not only shows governing compliance yet likewise works as a beneficial resource for future recommendation and enhancement.

When taking down scaffolding, it is important to utilize proper method to avoid crashes. Routine devices upkeep is necessary for risk-free procedures. Adhering to these practices ensures a safe work environment and reduces threats.

Weather condition impacts can considerably affect the security of scaffolding frameworks. Rainfall can compromise structural stability, causing prospective collapse. Monitoring weather and taking essential precautions, such as safeguarding the scaffolding, are essential to maintaining a risk-free work environment.

When dealing with unequal or sloped surfaces, stability problems are critical. Follow details standards for proper setup, making certain safety preventative measures remain in place. Routine devices upkeep is essential to uphold security and protect against accidents in such scenarios.

If a worker encounters a security issue while using scaffolding, they must immediately quit working, report the trouble to their manager adhering to the reporting procedure, and if essential, trigger the emergency action procedure to assure every person's safety.

Scaffolding tools need to be replaced according to an established routine based on producer guidelines and use regularity. Updating regularity must line up with technological innovations. Regular assessments and appropriate upkeep are crucial to guarantee safety conformity.

To sum up, appropriate scaffolding preparation is crucial. This consists of choose ideal materials, guaranteeing secure setting up, carrying out normal examination and upkeep, training workers on safe practices, and guaranteeing compliance with policies. By adhering to these ideal practices, the risk of crashes and injuries can be greatly lowered, developing a more secure workplace for all people associated with scaffolding procedures.

This thorough strategy to scaffolding safety emphasizes the value of comprehensive preparation, effective interaction, and ongoing watchfulness in preserving a secure work environment.