Rapid Prototyping vs. Typical Production: A Relative Evaluation of Modern and Traditional Approaches

In the realm of item development and manufacturing, the development of rapid prototyping has introduced a standard shift, testing the conventional production methods that have actually been the market requirement for years. This post offers a comprehensive comparison between rapid prototyping and typical manufacturing, examining their approaches, advantages, limitations, and the influence they have on the product advancement procedure.

Comprehending Rapid Prototyping and Traditional Production

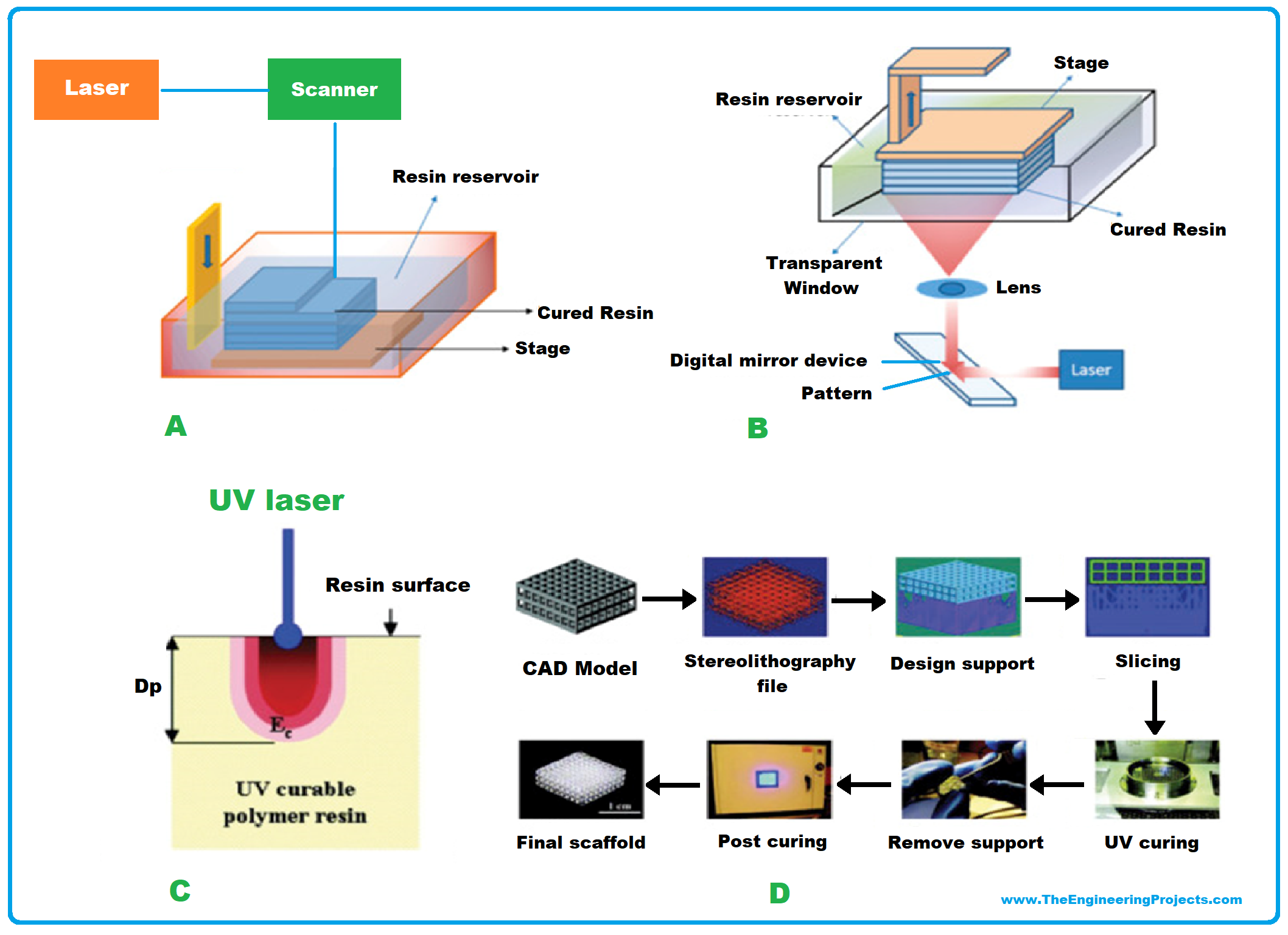

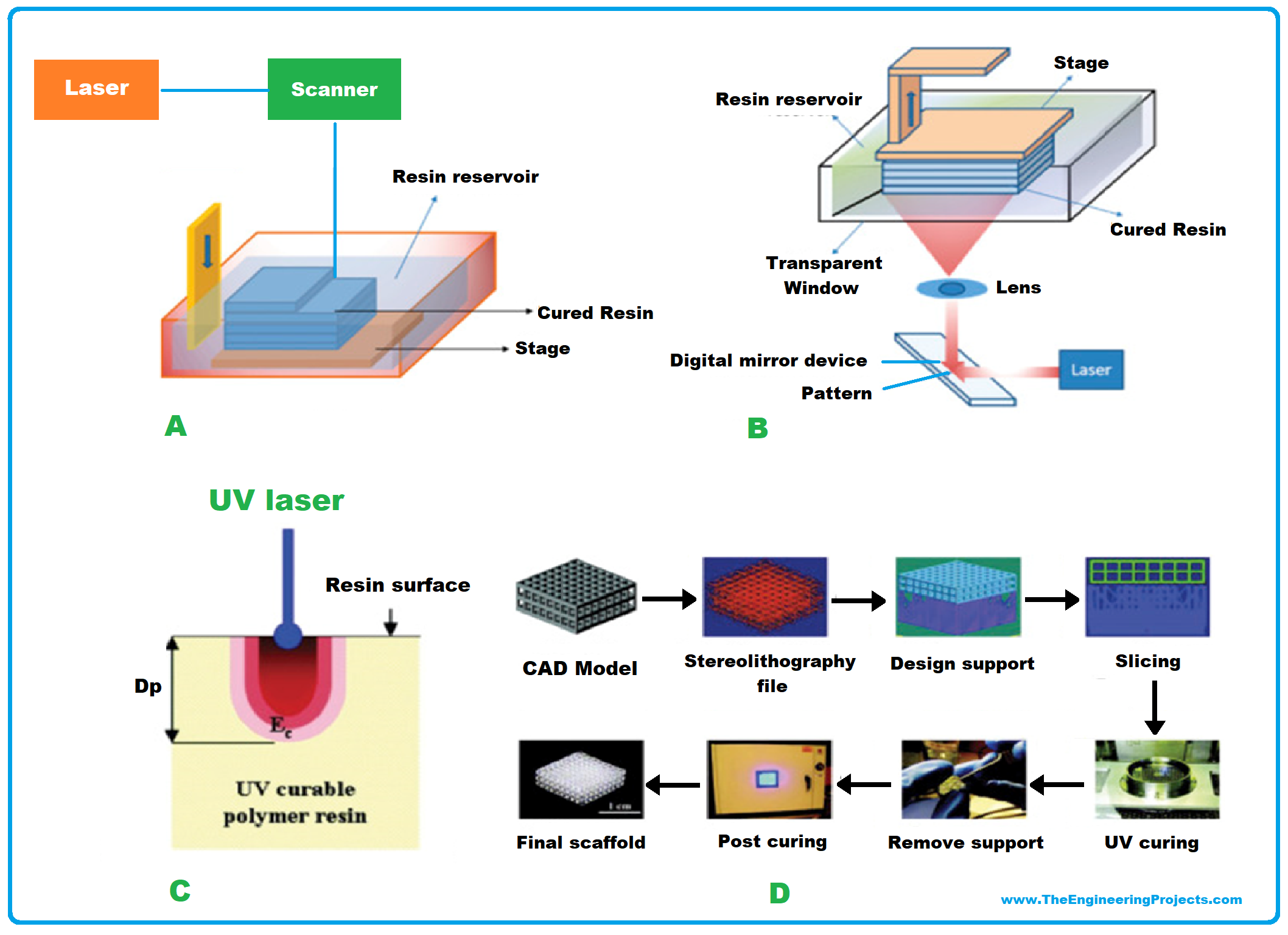

Rapid Prototyping: Rapid prototyping includes a team of strategies utilized to rapidly fabricate a scale design or part utilizing 3D computer-aided layout (CAD) information. It largely includes additive manufacturing or 3D printing, where an item is developed layer by layer.

Standard Manufacturing: Typical manufacturing methods consist of procedures like shot molding, machining, and spreading. These procedures usually entail subtractive techniques or making use of mold and mildews and are recognized for their high-volume manufacturing capabilities.

Speed and Adaptability

Time Performance: Rapid prototyping significantly minimizes the time from style to model, typically taking only days or hours, compared to conventional approaches that can take weeks or months.

Layout Flexibility: Rapid prototyping allows for better flexibility in layout adjustments and models. Typical production, with its dependence on mold and mildews and tooling, is less adaptable to design alterations as soon as the procedure has begun.

Cost Ramifications

First Expenses and Configuration: Conventional manufacturing typically calls for significant first investment in tooling and arrangement, making it economical for massive manufacturing however expensive for small sets. Rapid prototyping, while having reduced initial configuration costs, can be more affordable for small-scale manufacturing and prototypes.

Economic situations of Range: Typical manufacturing techniques end up being much more cost-effective at higher quantities as a result of economic situations of range, whereas the expense of rapid prototyping remains relatively constant no matter the amount created.

Product and High Quality Considerations

Material Variety: Rapid prototyping provides a wide variety of materials, consisting of plastics, resins, and steels. Typical manufacturing also supplies a selection of materials but is frequently limited by the restrictions of the particular manufacturing process.

Quality and Finish: Traditional manufacturing methods commonly generate parts with superior strength and coating contrasted to rapid prototyping. Nonetheless, developments in rapid prototyping innovations are constantly narrowing this high quality space.

Application and Suitability

Prototyping vs. Mass Production: Rapid prototyping is suitable for prototyping and small production, enabling rapid testing and growth.

cnc machining China stays the best technique for automation because of its efficiency and capability for large volumes.

Customization and Intricacy: Rapid prototyping master creating facility and personalized components without extra cost, a task that can be challenging and expensive in conventional production.

Ecological Impact

Waste Manufacturing: Rapid prototyping, especially additive production, commonly produces much less waste compared to typical subtractive techniques, which can be more wasteful of materials.

Energy Intake: Traditional manufacturing techniques, especially those involving high temperatures and pressures, can be energy-intensive. Rapid prototyping's energy consumption varies depending on the innovation used.

Future Outlook and Adjustment

Technical Advancements: Constant developments in rapid prototyping innovations are expanding its capacities, making it progressively competitive with traditional manufacturing in terms of quality and product residential or commercial properties.

Crossbreed Methods: Several industries are taking on a hybrid strategy, leveraging the strengths of both rapid prototyping and typical manufacturing to optimize the item advancement process.

Verdict

Rapid prototyping and standard manufacturing each have their distinctive advantages and constraints. The choice in between both depends upon various elements, consisting of the job's scale, complexity, material requirements, and price considerations. As technological advancements remain to advance, the line between these 2 techniques is ending up being significantly obscured, with each embracing aspects of the other to improve effectiveness and performance in item advancement. The future of producing depend on the strategic combination of these techniques, using the most effective of both worlds to drive development and productivity.